Sitilakichala

Zipangizo

Din 1.4404 / Aisi 316l, Din 1.4539 / Aisi 904l

Montel, Spancesel, Repelle, FOSTOLLOY Endos

Zinthu zina zopezeka pempho.

Fluzeni Ubwino: 1 -200 Microns

Kulembana

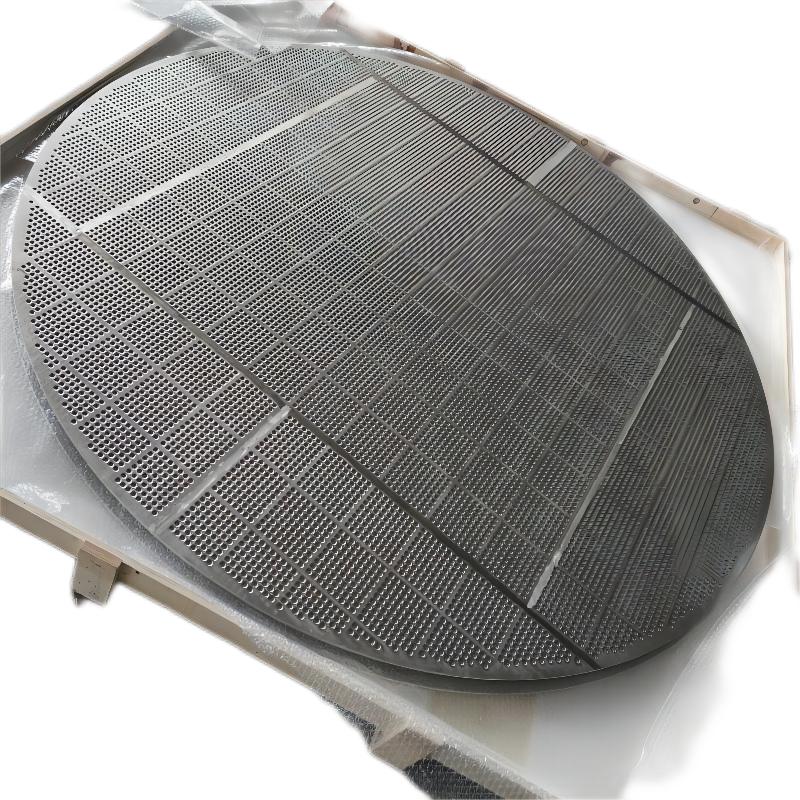

| Kutanthauzira - kulumikizidwa mbale zopachika maya | ||||

| Kaonekeswe | flumwa Kukongola | Sitilakichala | Kukula | Kupanikiza |

| μm | mm | % | ||

| SSM-P-1.5t | 2-100 | 60. 60 chosambira + 60 + 30 + φ4x5px1.0t | 1.5 | 57 |

| Ssm-p-20t | 2-100 | 30 Oseketsa + 30 + 30 + φ5x7px1.5t | 2 | 50 |

| Ssm-p-2hir | 19-100 | 60.0 | 2.5 | 35 |

| Ssm-p-3.0t | 2-200 | 60. 60 wosanjikiza + 60+ 20 + 20 φ6x82.0t | 3 | 35 |

| SSM-P-4.0t | 2-200 | 30 "wosanjikiza + 30 + 20 φ8x10px2.5t | 4 | 50 |

| SSM-P-5.0t | 2-200 | 30 * Okwerera + 30+ 20 + 16 + 10 φ8X10px3.0t | 5 | 55 |

| SSM-P-6.0t | 2-250 | 30 wosalala + 30 + 20 + 20 + 10 φ8x10px4.0t | 6 | 50 |

| SSM-P-7.0t | 2-250 | 30 wosalala + 30+ 20 + 16 + 10 φ8x10px5.0t | 7 | 50 |

| SSM-P-8.0t | 2-250 | 30 wosalala + 30 + 20 + 20 + 10 φ8x10px6.0t | 8 | 50 |

| Kukula kwa mbale yolumikizira ndi kapangidwe kaya kwa ma waya kumatha kusinthidwa malinga ndi zomwe wogwiritsa ntchito. | ||||

Mawu, ngati akugwiritsidwa ntchito m'masamba owuma moto othilira, mawonekedwe osefera amatha kukhala osanjikiza asanu ndi atatu opindika.

Izi ndi 100. Ndiwo 100 Osefesensi + 100 + 12/64 + 64/12 (kapena 10)

Kukula kwa mbale yolumikizira kumadaliranso thandizo lanu.

Izi ndizabwino m'malo ophatikizika kwambiri kapena kufunikira kwakukulu kotheratu, kuthana ndi kugwiritsa ntchito pafupipafupi kwa makampani opanga mankhwala ndi mankhwala komanso zopangidwa ndi zinthu pa intaneti.

Mapulogalamu

Chakudya ndi chakumwa, chithandizo chamadzi, fumbi kuchotsa, mankhwala, mankhwala, police, ndi zina.

Mafuta owoneka bwino ndi maungusi amene amachimwa kwambiri ndi mauna ofuula ndi mauna owiritsa. Pulogalamu yolimba imatha kusankhidwa mwanjira zosiyanasiyana malinga ndi zosowa, ndipo ukonde woluka ukhoza kukhala chimodzi kapena zingapo. Chifukwa cha mbale yolumikizira ngati chithandizo, mauna ophatikizika ali ndi mphamvu yovuta kwambiri komanso mphamvu yamakina. Kuchimwa kwa ziwirizi sikumangokhala ndi ma mesh abwino ophatikizika, komanso ali ndi mphamvu yamakina ya mbale yotentha. Itha kukonzedwa mu cylindrical, disc, pepala, zosefera kwambiri pamadzi, chakumwa, chakudya, zakudya, mafakitale a mankhwala, etc.

Zopangidwa ndi mitengo yamiyendo yolakwika:

(1) Kukhazikika kwabwino ndi mphamvu zapamwamba kwambiri. Chifukwa cha kuchirikiza mbale ya mbale, kumakhala ndi mphamvu yayikulu kwambiri yolemetsa ndi nyonga yolemetsa pakati pa mafinya olakwika;

.

.

.

.

Kugwiritsa ntchito mbale zomwe zatsutsidwa:

(1) Zipangizo zomwe zimagwiritsidwa ntchito pomwaziritsa kuzizira kwambiri.

.

.

.

(5) Kufalikira, kuchapa ndi kuyanika kwa zida m'mafakitale opangira mankhwala.

(6) Chothandizira Chuma.

.